Synopsis: Spalting, the inner coloring brought on by fungi in wooden, provides an ideal alternative for wooden turners to enliven their work. The gorgeous colours and patterns are present in home in addition to unique woods, and would possibly even be as shut as your firewood pile. Nonetheless, as a result of spalting is principally an indication that wooden is deteriorating, there are methods to decide on wooden properly and work with it rigorously to provide easy cuts. Here’s a information to working with spalted wooden, from selecting it, to turning it, to ending.

Richly coloured and patterned woods are prized by turners, however unique species and burls could be each dear and laborious to show. Spalted woods supply a better path to eye-catching work.

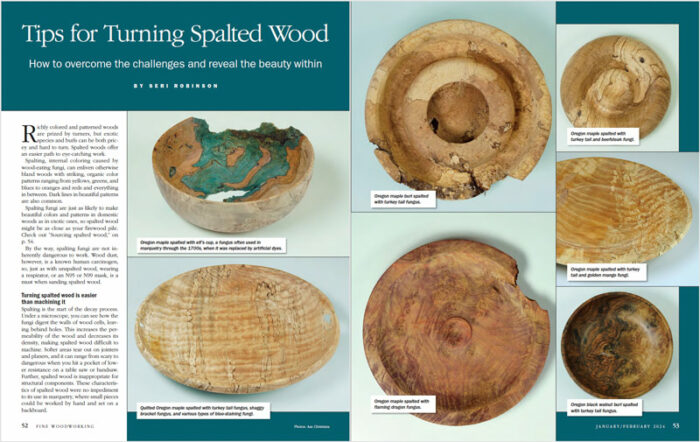

Spalting, inner coloring brought on by wood-eating fungi, can enliven differentsmart bland woods with putting, natural colour patterns starting from yellows, greens, and blues to oranges and reds and all the pieces in between. Darkish strains in lovely patterns are additionally frequent.

Spalting fungi are simply as more likely to make lovely colours and patterns in home woods as in unique ones, so spalted wooden is perhaps as shut as your firewood pile.

By the way in which, spalting fungi aren’t inherently harmful to work. Wooden mud, nevertheless, is a identified human carcinogen, so, simply as with unspalted wooden, carrying a respirator, or an N95 or N99 masks, is a should when sanding spalted wooden.

Organising for fulfillment

Spalted wooden is weaker and fewer constant than sound wooden, so that you’ll have to decelerate and use very particular strategies. Nevertheless it’s nicely value the additional effort.

TipThe fingernail check. Press laborious along with your thumbnail to guage punkiness and decay. A deep dent reveals weak construction, discovered the place white rot has progressed considerably. |

Sourcing spalted woodenSpalted wooden is perhaps as shut as your firewood pile or native big-box retailer, hiding in piles of ordinary oak, maple, and pine. Some shops even carry “blue” or “denim” pine with blue spalting. It’s also possible to discover spalted lumber at retail hardwood shops, from impartial, native companies to chains like Rockler and Woodcraft. There are additionally specialty retailers on-line, resembling Prepare dinner Woods, who will ship you spalted turning blanks in quite a lot of species. It’s also possible to spalt your individual lumber by introducing varied forms of fungi to sound wooden. I lined that course of and extra normal data for furnishings makers in a 2008 article titled “Spalted Wooden” (FWW #199), together with quite a lot of blogs on FineWoodworking.com. Wherever you get your spalted wooden, it will likely be a lot simpler to show whether it is absolutely dried, as a result of moisture exacerbates the variations in density between spalted and sound areas. Retail materials is more likely to be kiln-dried and have a low stage of overly delicate punkiness. You’ll pay a premium for it, however it should pay you again on the lathe. |

Turning spalted wooden is simpler than machining it

Spalting is the beginning of the decay course of. Beneath a microscope, you may see how the fungi digest the partitions of wooden cells, forsaking holes. This will increase the permeability of the wooden and reduces its density, making spalted wooden tough to machine. Softer areas tear out on jointers and planers, and it might vary from scary to harmful whenever you hit a pocket of decrease resistance on a desk noticed or bandsaw. Additional, spalted wooden is inappropriate for structural parts. These traits of spalted wooden had been no obstacle to its use in marquetry, the place small items could possibly be labored by hand and set on a backboard.

Woodturning, against this, is likely one of the greatest methods to work with spalted wooden. For one factor, turned work isn’t at all times purposeful or structural. One other benefit is the management that turning provides. Whereas most woodworking machines are inclined to spin at a set pace, with the blade dropped at the wooden at a set angle below steady stress, these components could be diversified on a lathe and adjusted on the fly.

With the suitable instruments and strategies, you may decrease tearout as you flip, and produce easy cuts in all kinds of spalted wooden. And that’s factor, as a result of spalting makes it more durable to scrub up main issues within the regular method—by sanding the piece whereas it’s spinning on the lathe.

Stabilizers normally aren’t vital—Some turners suppose that so as to flip spalted wooden efficiently, it should be absolutely stabilized by injecting resin or glue into it. However among the punkiest items could be turned efficiently utilizing the strategies outlined on this article. That stated, I do generally stabilize cracks and punky areas with a squirt of cyanoacrylate (CA) glue.

Turning the skin of a bowl

Robinson makes use of a faceplate whereas turning the outside and provides a small foot that will probably be held in a chuck for turning the inside.

Select blanks and varieties properly

Simply because you may flip any piece of spalted wooden efficiently, that doesn’t imply it’s best to. Not every bit deserves to be turned. You’ll have to stability its magnificence with the potential tearout, stabilizing, and sanding you’re prepared to place up with.

And regardless of how good you get at evaluating spalted blanks, you may nonetheless anticipate a failure fee of roughly one-third, in my expertise, from huge injury, cracks, and sudden levels of rot.

Contemplate the kind of spalting—White rot is probably the most harmful sort of spalting. If it’s too superior, your spalted wooden is firewood. Nonetheless, some white-rot fungi secrete darkish pigments that construct up on the edges of colonized areas, creating so-called zone strains, which could be very lovely. These could make white rot value coping with. Pigmentation, particularly any coloring apart from that of white rot, is much less damaging to the wooden construction.

Bowls and platters work greatest—When beginning out turning spalted wooden, persist with fundamental varieties and thicker partitions. Broad bowls and platters are very best, as they provide a lot of help for the slicing forces and showcase spalting fantastically.

Spindles will also be turned from spalted wooden. There aren’t that many makes use of for non-structural spindles, nevertheless, so I’ve targeted on bowl and platter varieties on this article.

Turning the within of a bowl

Remount the bowl utilizing a four-jaw chuck to safe it. The identical strategies that had been used on the skin of the bowl can be utilized for the within.

Secrets and techniques of success

Sooner speeds normally make wooden simpler to show. However spalted wooden has dramatic variations in density, which might throw blanks out of stability, so slower speeds are advisable.

It’s particularly vital to go gradual when roughing spalted blanks to spherical; keep at speeds beneath the purpose at which the lathe begins shaking. This may assist faceplate screws keep their maintain and likewise pressure you to make gentle cuts, which is able to make it easier to keep away from blowing up the piece.

Utilizing tough, aggressive cuts to rapidly spherical a tough clean will take huge chunks out of spalted materials. As a result of heavy sanding isn’t actually attainable on this materials, it’s essential take lighter, comparatively clear cuts to start out with. Scraping instruments are one other no-no, for a similar causes.

Whereas your preliminary cuts will inevitably trigger some tearout, it may be eradicated as quickly because the floor is absolutely spherical and unbroken. That is carried out by protecting the bevel of the device involved with the wooden as you lever the tip into the lower. Using the bevel will stop the tip from diving into softer sections.

As a result of aggressiveness is the alternative of what we would like in spalted materials, a conventional bowl-gouge grind is greatest. This grind falls within the center between the 2 extremes—flat “backside feeders” and pointy fingernail grinds—providing a bevel that’s large sufficient to make a easy transition between the facet and backside of a bowl.

Sanding and ending

Spinning a bit on the lathe for sanding doesn’t work nicely with spalted wooden. Robinson spins the abrasive as an alternative of the work.

When to repair it and when to pitch it

|

Sanding and ending are completely different—Your first aim is to keep away from tearout within the first place, which is able to stop extreme sanding. However sanding continues to be vital.

The issue with sanding spalted wooden within the regular method, whereas the piece is spinning on the lathe, is that the softer areas will probably be eliminated rather more rapidly than sound ones, resulting in an more and more bumpy floor.

One of the simplest ways to sand spalted initiatives is to spin the sandpaper, not the mission, utilizing a small mandrel that may be mounted in a drill press or handheld drill. The sandpaper takes the type of hook-and-loop disks, hooked up to a delicate foam pad.

I’m normally in a position to begin sanding at 220 grit, and it doesn’t take lengthy to take away device marks and easy out the floor. Then I transfer up by way of 600 grit a minimum of, going as excessive as 2,000 to provide a buttery delicate floor that reveals off the spalting fantastically, and desires no ending in any respect.

I keep away from finishes on spalted wooden. The worst are oil-based finishes, whether or not they construct a movie or not, due to the way in which they penetrate spalted wooden inconsistently, making a various sheen.

When you should end a spalted piece—as a result of it will likely be used and dealt with usually, for instance—water-based acrylic finishes, resembling Deft Acrylic, work nicely, as do true lacquers, like Deft’s brushing and spray-can variations.

–Seri Robinson is a professor of wooden science, and an avid woodturner.

Photographs: Asa Christiana.

To view the entire PDF, click on on the “View PDF” button beneath:

From Effective Woodworking #308

Join eletters right now and get the most recent strategies and how-to from Effective Woodworking, plus particular provides.

Obtain FREE PDF

whenever you enter your e-mail tackle beneath.